To the manufacturing industry of choice in the world

We aim to be the company of choice in the world not only by high technology but also by continuing to pursue the needs of our customers.

With production bases in Japan, China, Thailand, and Malaysia, we provide quick delivery and total cost reduction through an integrated production system from casting / trimming to finishing / machining.

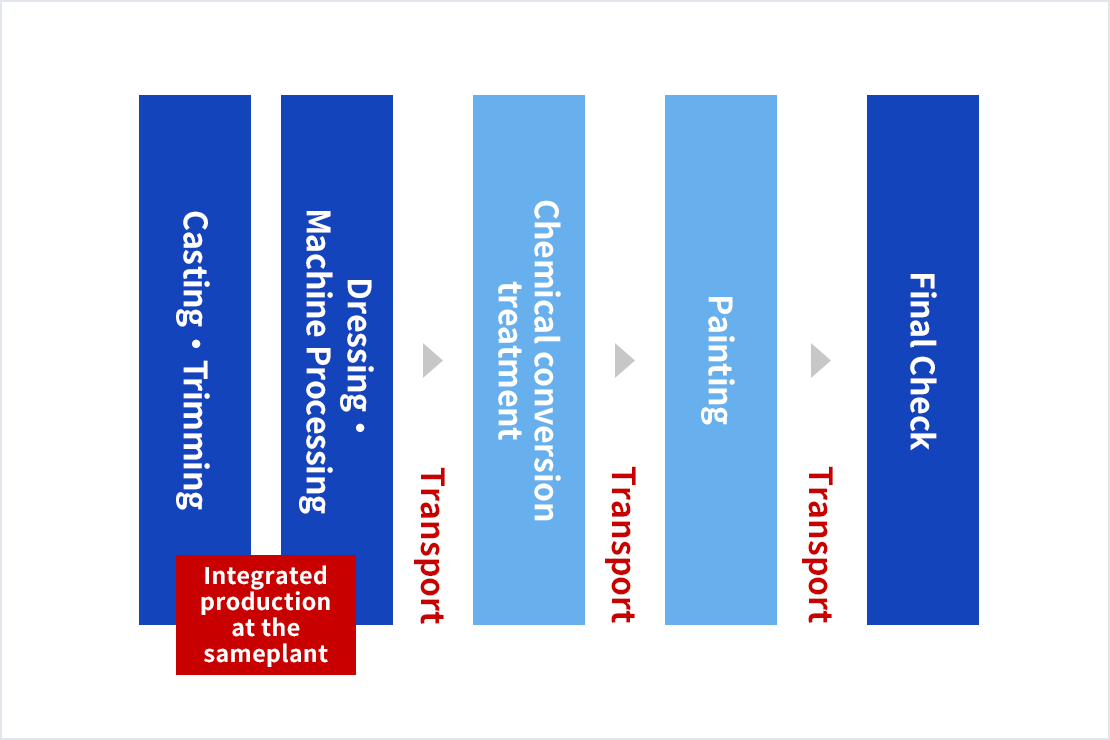

Providing short delivery times and cost reductions through an integrated production system

It is possible to consistently handle 5 processes from “casting / trimming” to “final inspection”. As a result, it is possible to reduce distribution costs between processes, ensure quality through technical cooperation, and carry out highly difficult manufacturing through comprehensive proposals, and meet needs such as cost reduction and quick delivery.

Global expansion that can handle small lots and large lots

High-precision products and value-added products with fewer lots can be produced in Japan, low-cost products with larger lots can be produced in foreign countries, and so on can be produced in foreign countries to meet customer needs for communication pattern and delivery.

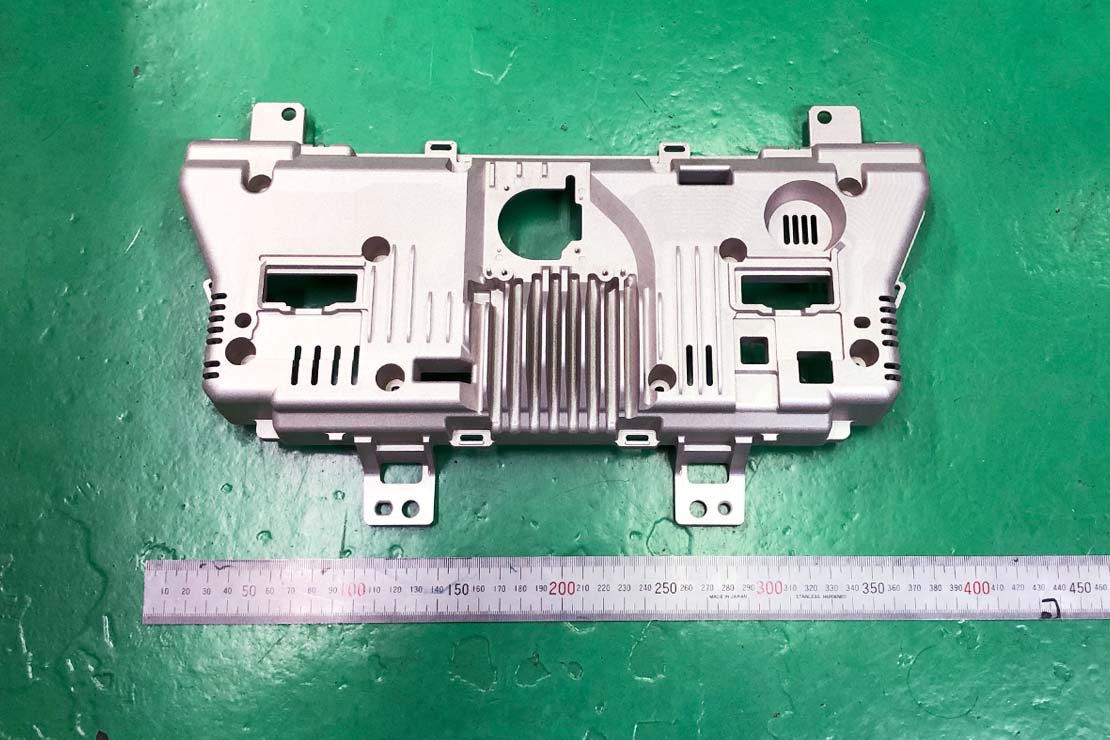

Support for products with strict dimensional accuracy

In order to realize the product specifications and applications required by customers, this product meets the strict dimensional tolerances required for cast materials. Specifically, we have achieved material dimensional tolerance of 0.03 mm and thinness of 0.35 mm. We are also equipped with optimization using simulations and inspection systems using 3D scanners.

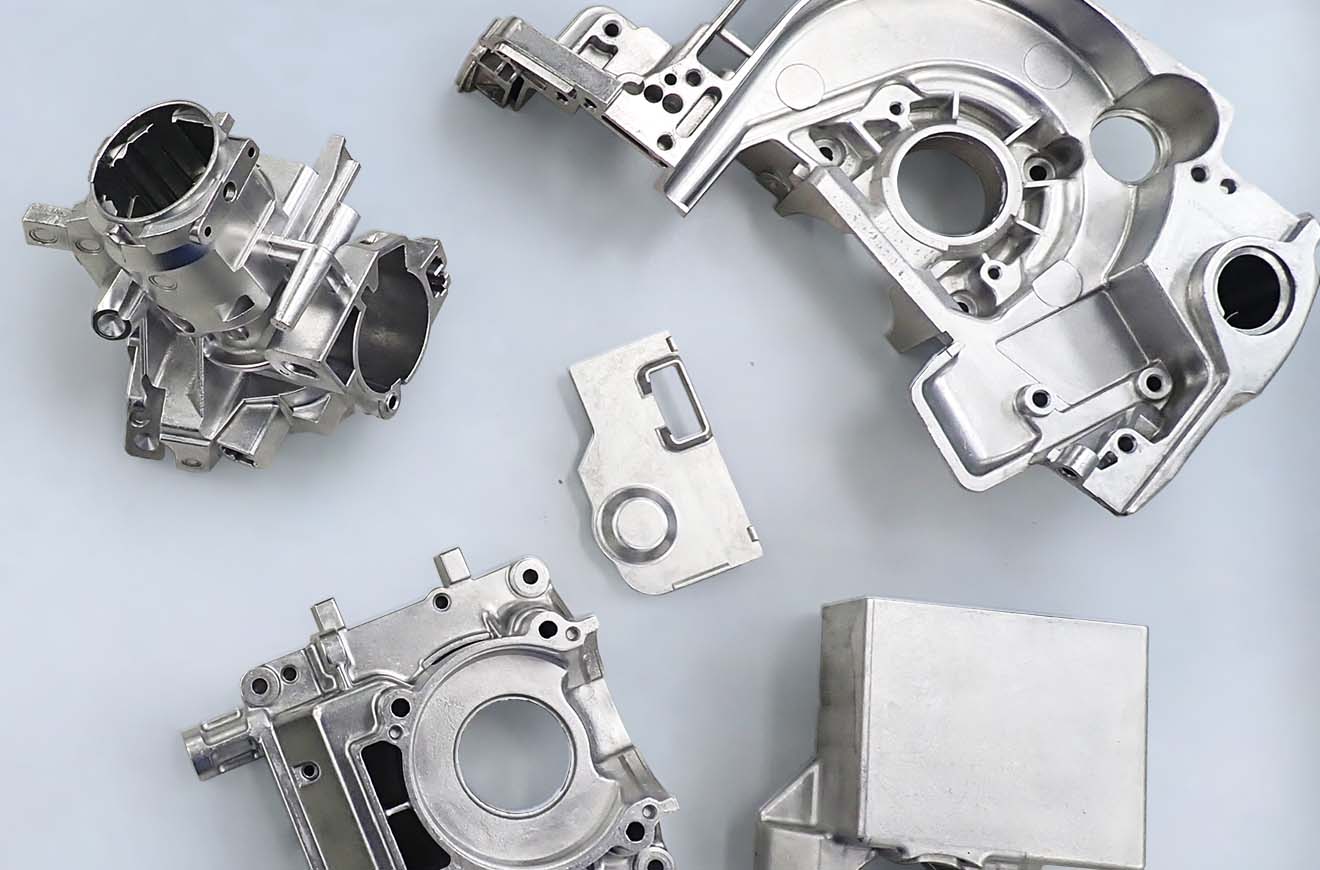

Product manufacturing performance in diverse industries

We have a track record of manufacturing products in various industries such as automobile parts, communication equipment, medical equipment, industrial equipment, OA / office equipment, etc. We can mold parts according to your needs. In particular, we will take advantage of the “lightness” that is the most characteristic of magnesium alloys, and at the same time, we will meet the needs of our customers in all QCD.

Supports processing of a wide range of parts from difficult-to-cut materials to resin

We propose the optimum processing method according to the customer’s product specifications and applications by making full use of high-quality surface finishing and precision processing technology that cannot be imitated by other companies. We also have various VA / VE cost reduction proposals and a mass production system with 24-hour production. Only secondary processing is available. Please feel free to contact us.